Inside many electric motors, AC or DC, you’ll find a circle of magnets working to spin your appliance or propel you down the road. Magnets, along with lithium and other EV staples, are an increasingly hot commodity these days.

Burgeoning demand in the midst of supply security concerns puts EV manufacturers in a tight spot, further compounded by component shortages and shipping delays around the world.

Rare earth magnets like neodymium have substantial magnetic energy for their volume. China leads the world in processing and supplying magnets for EV applications, which further complicates the situation for vehicle manufacturers beyond their borders. Magnet prices have risen dramatically over the last decade, spurred in part by a sea change in EV demand. The environmental costs of magnet production further muddy the waters for an industry obsessed with being green.

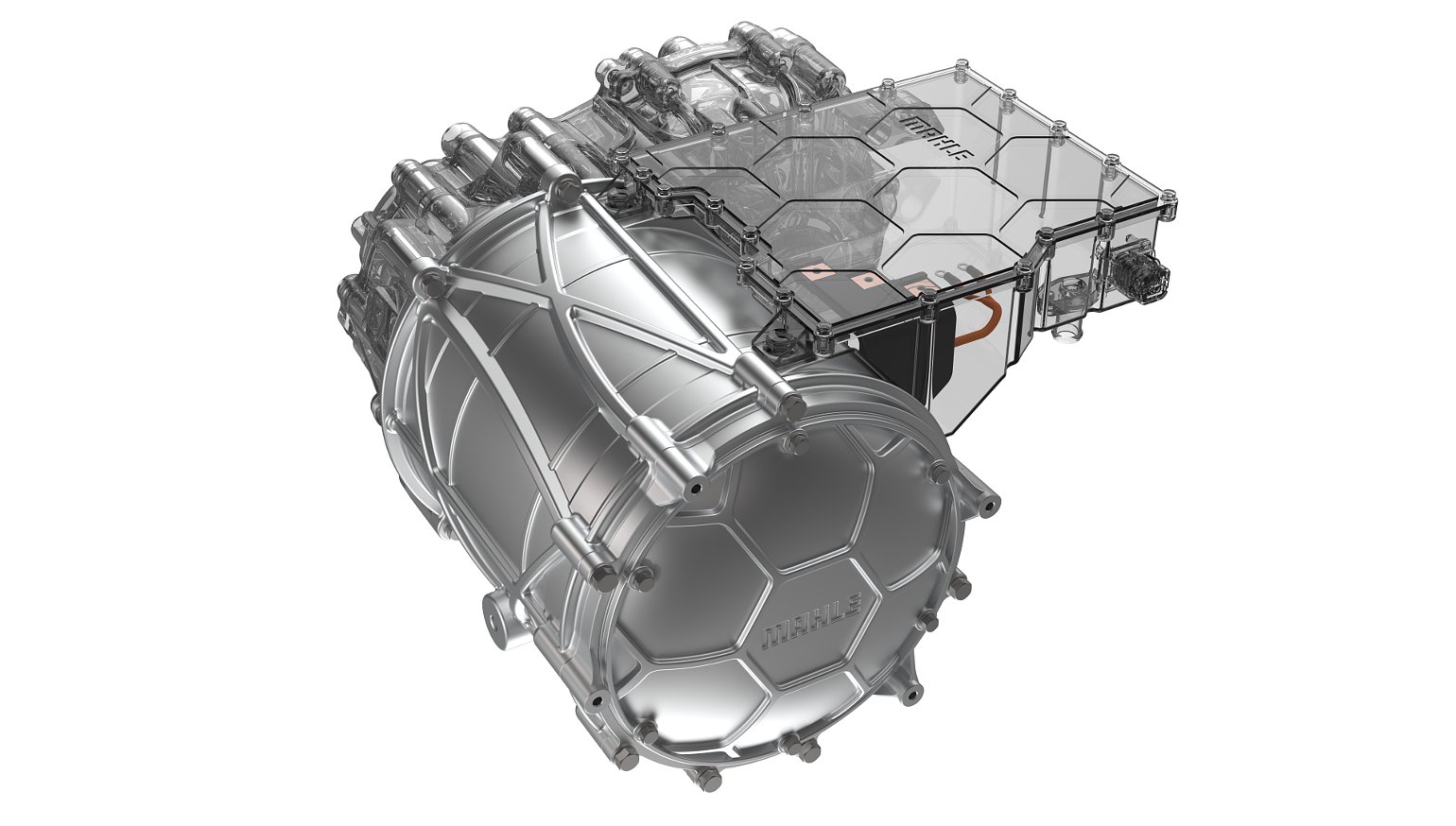

Why not use an electric motor that doesn’t need magnets? Rare earth magnets are tough to beat in an EV motor application, balancing decent performance, relative longevity, and affordability in an energy-dense form. Designs that do not use physical magnets need physical connections to get power to rotating coils. This introduces wear surfaces and yet another drain on EV’s power source. Induction motors are a promising alternative, but they can be expensive and inefficient. German powertrain giant Mahle revisited the induction design to create their new electric motor. (If Mahle sounds familiar, you've probably seen their name on a variety of motorcycle parts like oil filters, pistons, and rings.)

Existing tech, new process

The new motor is no less than 95 percent efficient and, according to Mahle, only Formula E cars could match that performance. (Ever listen to Formula E cars?) The separately excited, asynchronous design uses a contactless transformer to induce a magnetic field to spin the rotor. Mahle's innovation here is their optimization process, employing advanced simulations instead of building countless test motors. This dramatically shortened development time. Another advantage of this approach is tuneability; the concept can be scaled to suit many applications by adjusting the coil windings. Permanent magnet designs must work around the magnet's existing field properties.

“With our new electric motor, we’re living up to our responsibility as a sustainably operating company,” says Michael Frick, Chairman of the MAHLE Management Board (ad interim) and CFO. “Dispensing with magnets and therefore the use of rare earth elements offers great potential not only from a geopolitical perspective but also with regard to the responsible use of nature and resources.”

“Our magnet-free motor can certainly be described as a breakthrough, because it provides several advantages that have not yet been combined in a product of this type,” says Dr. Martin Berger, Vice President Corporate Research and Advanced Engineering at MAHLE. “As a result, we can offer our customers a product with outstanding efficiency at a comparatively low cost.”

Global issues drive innovation

Mahle repeatedly cited “resource security” and rare earth mining as major obstacles in electric motor production and design. Their press materials suggest that future EV powertrains could be affordable, powerful, and magnet-free. This could be welcome news for the global electric motorcycle industry as it struggles to increase performance and lower MSRPs, not that Mahle is worried. The sprawling ICE side of the business is hard at work, too, with innovations like 3D printed pistons to push the limits of engine performance. Mahle can afford to play both sides.

This new electric motor design seems ideal for an electric motorcycle application. Bikes have severe packaging constraints when it comes to motors, batteries, and other EV components, so Formula-E levels of performance in a cheaper, magnet-free format would be a welcome boost. Some argue that better motors, not batteries, are the key to next-gen EVs. Then again, Tesla moved away from induction to an advanced permanent magnet arrangement with the 2019-on Model 3 for a minor gain in efficiency. It’s anyone’s game.

Motorcyclists can be a demanding bunch. Even so, it’s not wrong to want a riding experience that approaches or exceeds your favorite ICE bike’s range, acceleration, and real-world rideability. Mahle doesn’t explicitly promise any of that from this motor. Instead, this development is another step in the steady, incremental improvement of EV tech as we watch for the next generation of electric motorcycles. It’s also a reminder that the future of EVs is inextricably connected to the global and, at times, unpredictable supply chain that heavily influenced Mahle's strategy for this project.

The first units might be available in three years. Predictably, Mahle hasn't released any white papers with full tech specs for these motors yet. What other innovations might arrive in the meantime? It’s safe to say the best electric motorcycles haven’t been built yet.