Gaskets seal gaps between surfaces, keeping your engine’s fluids and gasses where they belong. We don’t pay much attention to them.. until they fail.

Gaskets are made from deformable materials like paper, rubber, cork, synthetics, or composites. Special gaskets are made from fiberglass, felt, and other materials for specific applications. High-heat environments, like exhaust connections, may use metal gaskets. This article will focus on making your own general-purpose flat gaskets for simple things like water pumps, intake manifolds, engine covers, and oil pans.

Why make your own gaskets?

It’s almost always easiest to order whatever gasket you need and install it when it arrives. Even so, every home mechanic should keep a few sheets of gasket paper handy. Sometimes the part you need is out of stock, or it won’t arrive in time for an upcoming trip. For a custom or antique motorcycle, cutting your own gaskets may be your only option.

There’s always the price factor, too. A $10 roll of gasket paper can provide many times its value with a little effort.

What about RTV/liquid gasket?

When a gasket fails, many folks reach for their favorite goop to seal up the mating surfaces. Every home mechanic should also keep a tube of the stuff around, because it’s cheap and useful, but liquid gaskets aren't the solution to every problem. A good rule of thumb is to follow the factory’s specification. Many two-stroke crankcases, for example, should only be sealed with a specific liquid gasket material. On the other hand, an oil filter cover that is occasionally removed would be better off with a rubber-fiber gasket.

Anecdotally, a used engine dripping with sloppy RTV is a red flag. Why not buy or make the correct parts? What other shortcuts were taken by the previous owner? Once you know how to cut your own gaskets, there’s no excuse for glob jobs where they aren’t needed.

Tools for making gaskets

Thankfully, you don’t need any special tools to start making your own replacement gaskets. There are a few non-essential tools that can provide a much cleaner result, but for the basics, you’ll need the following:

- Scissors

- A hobby knife with a fresh blade

- A sharp pencil or a fine pen

- A ruler or straight edge

- Common wheel and bearing grease

- An old cutting board, hobby mat, or scrap of wood for your work surface

Choosing the right gasket materials

Which gasket material is best for your project? Follow the factory’s lead, paying attention to the old gasket’s thickness and material. When it's time to buy some gasket stock, a good starting point is Fel-Pro’s 3060 gasket kit ($8-$10), easily sourced online or at your local auto parts store. Countless bulk options are available online if you can afford to wait for shipping. Still not sure what material to use? 1/32-inch rubber-fiber sheet is my go-to for oil, coolant, or gas, and any auto parts store should have it in stock.

How to trace and cut gasket shapes

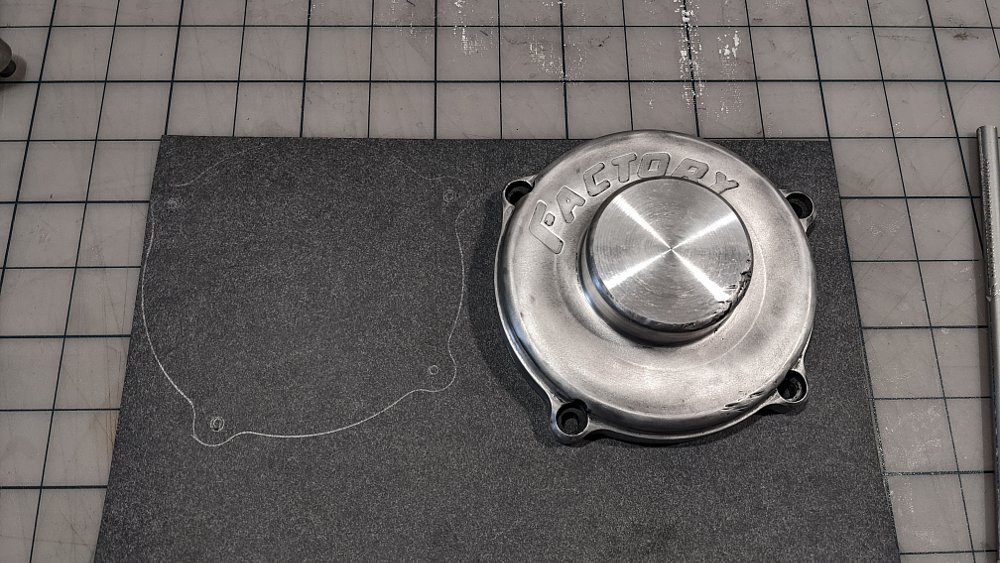

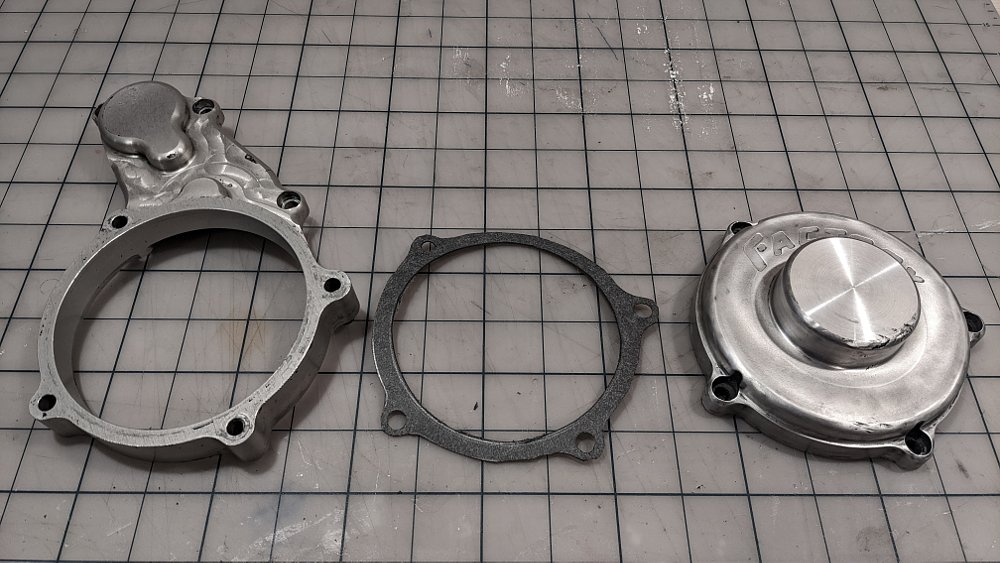

I recently picked up an old billet starter cover for one of my motorcycles. It didn’t come with any gaskets, so it’s a great candidate for a DIY job. Start by looking over the mating surfaces you’re trying to seal, paying special attention to any oil or coolant passageways through the parts and relevant gaskets. (Failure to account for these features can lead to serious engine damage!) Refer to images of the factory gaskets, if possible, to make sure you’re creating a 1:1 replica. Carefully clean the mating surfaces of grime and old gasket material.

Lay the mating surface flat on the gasket paper and trace its outline with a pencil. Mark any holes that you can access while holding the part in position and cut the shape free from the gasket material. Transfer punches can also be used to mark holes. Cut out the gasket and any bolt holes.

The gasket’s inside contours are a bit more difficult to trace in most situations. My parts are an exception because I can easily trace the inside line I need. Most covers don't have access like this, and there are a few solutions. One trick is to smear a thin layer of grease or oil over the mating surface, then press the gasket blank straight down onto it. This "prints" the outline you need to cut. Not very precise, and increasingly iffy after the first "printing," but there is no chance of harming the mating surfaces.

If you'll accept a little risk in exchange for a clearer line, you'll need a small brass or nylon hammer. Place the gasket over the part, using bolts to align everything if possible. Tap gently around the inside edge of the mating surface to create an impression of the shape. Work slowly around the inside, and did I mention tapping gently? Remove the gasket, cut along the impression lines, and you're all set.

Both methods will probably involve some adjustment. Check the fit, trim a little more, and check again. Just take your time. Check over the gasket one last time to make sure that it's correct and then install it. Consider making a spare while you have all your supplies and tools out if this gasket is usually hard to find.

With these techniques, you can replicate almost any flat gasket on your motorcycle's engine. Easy, cheap, and effective. A humble sheet of gasket paper has saved me from missing a trip more than once, so keep a sheet around. If you never need it, so much the better!