"Desmo, brah."

Ducatisti around the world know that the red bikes have desmo valves. Not all of them can tell you what that means, exactly.

The Greek words desmos (bond) and dromos (track) from which the term is derived explain the concept to a degree: the paths of the rocker arms and the valve are married. This will start to make some sense after you know how the system works.

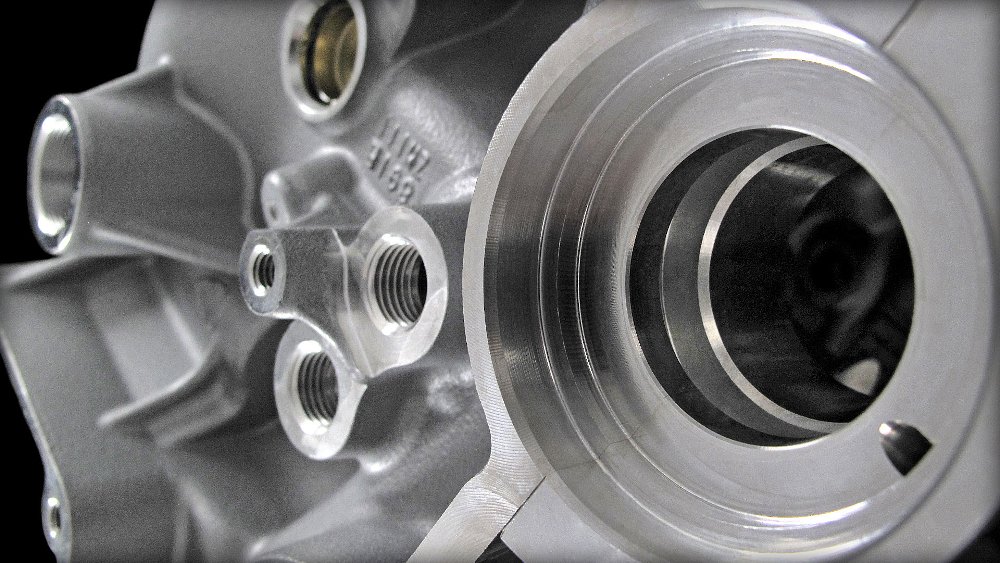

In almost every poppet valve system, valves are opened via mechanical actuation. For side-valve and many OHC engines, that means the cam’s lobe is pushing open the valve. (Yes, sometimes it acts on a rocker arm or a shim bucket, but the protrusion that is the lobe is handling the opening duties.) For those with pushrod engines, the same thing is happening, but the lobe works through some linkages (usually a lifter, pushrod, and rocker arm).

This is exactly the same in a desmo system. Where the desmodromic valve differs, however, is in the closin’. A conventional poppet valve relies on a valve spring, sandwiched between the head and a collar with keepers, to snap the valve shut. Desmodromic systems remove the valve spring and generally supply another rocker. Those who deal with standard poppet valves in an OHV or OHC setup tend to think of rockers as valve-opening devices, but there’s no reason they can’t be used to close the valve, too.

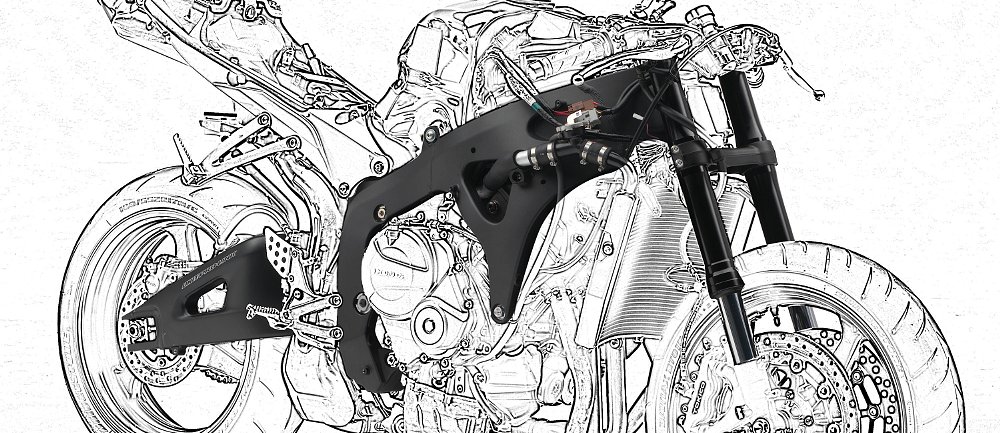

Contrary to opinion, Ducati did not invent the desmo valvetrain. In 1956, however, Fabio Taglioni, a Duc engineer, did develop a desmodromic valvetrain for a 125 single. Postwar Italy as a whole was still in precarious shape at that time. Ducati Meccanica, the motorcycle division, was questioning its very existence. In fact, in the first part of the decade, to lure Taglioni to the company, Ducati General Manager Giuseppe Montano grimly laid his cards on the table.

"I know your talent, and I need you," he said. "If you build a hundred motorcycles to win the Tour of Italy, Ducati will stay open, because I only have one month's salary for my workers. If not, we shut down and everyone goes home."

In six months, Taglioni produced a bike — the first Duc desmo. (He didn't draw a salary for that six months. Talk about believing in yourself, eh?) It kicked ass on the race circuit, and by 1967, Ducati's race-bred desmo system could be had in a consumer motorcycle.

So the big question is why? What does the desmo valve do that “standard” spring-operated poppets can’t?

The answer nowadays is “not too much,” but in the old days, that wasn’t the case. Taglioni was looking for a way to rev the shit out of an engine without breaking things, if you'll pardon my coarse terminology. Engine metallurgy of old kind of sucked. As such, valve springs would often break. This was somewhat acceptable, because engineers and customers alike prized the simplicity and large service intervals valve springs offered. In short, riders were accustomed to having a valve spring fail. (Think about how many valve spring breakdowns you have seen or even heard of in the modern era. We've come a long way.)

Racing motorcycles, however, are (and always will be) a different story. Simplicity and service intervals don't matter. Maximum performance was the order of the day — racers rode hard and beat the engines within an inch of their lives, just like today. They'd rev it to the moon and they didn’t care if the crew had to rebuild an engine after every race — just as long as it ran really well for a very short time.

The other problem associated with valve springs was the tendency of the valves within them to “float.” Float is a condition that occurs at high revs where the spring cannot close the valve fast enough to keep consistent pressure upon the valve through the entire closure phase. This can reduce an engine’s output and also creates a scenario whereby the valve timing is altered enough to actually cause catastrophic contact between valve and piston. (Using valves to ventilate the pistons is never a winning race strategy!) Stronger valve springs is one way to address this, but they have their own set of problems. The engine has to devote more work to opening the valves, and the increased spring pressure causes additional valvetrain component wear.

Perhaps Taglioni’s own explanation for the system is the most succinct. “The specific purpose of the desmodromic system is to force the valves to comply with the timing diagram as consistently as possible.” Now that Greek name for the system makes sense, right? Instead of blindly hoping the spring snaps shut and closes the valve and it doesn't float, desmo valves "bond" the rocker arms to the entire "track" of the valve's path, not just the opening half.

And nowadays? Well, most of the problems conventional valve springs have been solved through improved metallurgy and design. Breakage was solved largely by way of vacuum induction melting — a metal-refining process that helped remove the impurities that weakened early valve springs.

More careful examination of valve spring activity with high-speed photography showed that float was often caused by resonance. (Reverberation, if you will.) This is overcome today through the use of varying diameter springs and also by use of multiple springs. A modern 600 cc sport bike can comfortably redline at 16,000 rpm, quite a bit higher than the average Ducati, thus rendering most prior problems associated with valve springs fairly moot.

A more cynical writer prone to conspiracy theories might mention something about expensive espresso and the cost of servicing valves. I'm not that author. Servicing Duc valves isn't appreciably harder than any other make, and they've gotten their adjustment intervals to a point where I feel they're pretty reasonable relative to conventional poppet valves.

At this point, it should be plain to see why desmo valves are still in the game: because Ducati people like ‘em. Ducati uses the desmo system simply because they’re proud of their heritage, and they should be. Ducatis had humble origins and the company hasn't forgotten its roots. They close their valves using a quaint method that they have been using for a long time. Without Ducati, desmodromic valves would be a footnote in history, rather than active part numbers available for order. Desmo valves work fine. They're a different-yet-effective way to close a valve and as much a part of Ducati as “transverse” engines are to Moto Guzzi. (It should be noted that Taglioni also was the driving force behind the wildly successful L-twin. Note that Ducati still uses that, too!) Desmo valves are a technical anachronism but still useful, so they haven't been put out to pasture, kind of like your favorite WTATWTA author.

And in the future? I think it's possible that things could shift so that desmo valves once again have a performance edge. If you read my article on valve timing, you'll recall that many manufacturers are currently coaxing power from their powerplants by altering the valve timing. That's fine and good, but it only alters the timing of the intake and exhaust relative to one another. Varying valve duration is much more difficult to achieve using conventionally closed valves. However, because desmo valves can separate the mechanical events of opening and closing the valves onto different camshafts, adapting the existing phasing capability of something like the DVT system would enable variable duration rather easily. Naturally, there are packaging and usability constraints galore, but removing valve springs from the equation could make changing cam duration on demand possible.

For now, though, desmo valves are an engineering solution of the past that is part of Ducati's identity in the present. That’s why things are the way they are.