Compression ratio is an important determinant in an engine’s “personality.” Put simply, it’s a measure of how much air and fuel a cylinder in an engine can squeeze. It’s simply a comparison of how much volume it can hold at maximum size (when the piston is at bottom dead center) relative to the volume at its minimum size (all the way up at top dead center).

For an uncomplicated perspective, think of it in terms of pressure potential. By placing the fuel and air under more pressure, the potential to extract greater power from the (very rapidly) burning air and fuel mixture exists.

To give you a quick example, let’s imagine a single-cylinder engine with a bore of 3 1/2 inches and a stroke of 4 1/4 inches. To keep things easy, let’s say at TDC, the flat-top piston comes even with the top of the deck. Let’s also pretend that the volume of the head is eight cubic inches. Πr² is the formula we need to obtain the area of the bore, then we multiply that times the height to come up with a displacement of 40.88 cubic inches. Now we add in the volume of the combustion chamber and set up our ratio, which is 48.88:8. Compression ratios are always expressed with a denominator of one, so we simply divide the maximum volume of cylinder and chamber into the minimum to get a compression ratio of 6.11:1. Make sense?

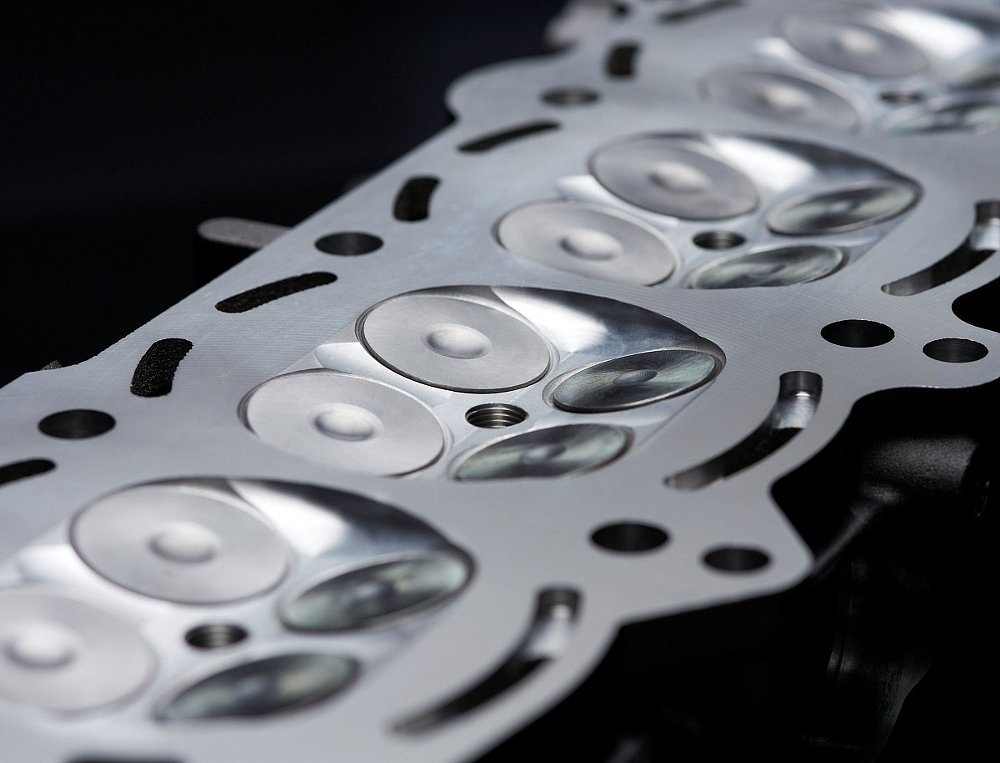

Now, this is a simplified comparison. There are some other factors to complicate matters a bit. For instance, compression ratio can be raised or lowered by using a thicker or thinner head gasket. (Or no head gasket at all!) It can also be altered by using pistons that have different shapes, as well. For example, our theoretical piston up there had a flat top, but what if it had a dish for the valves, or if it didn’t come all the way up to the deck? (The “deck” is the top of the cylinder.) Combustion chamber volume would increase, and compression ratio would then decrease. The converse is true for items like “popup” or domed pistons; those reduce the combustion chamber’s volume.

As a side note, we've been talking about static compression ratio, not dynamic. We're talking about compression ratio with the engine standing still, but the reality is that engines move at lots of different speeds. In order to make some high-revving engines work well, there is a fairly long period of time where the intake and exhaust valves are both open. Part of the reason modern compression ratios have gotten so high is simply to help compensate for that overlap.

So you might be wondering why we don’t just jack up the compression ratios like mad so we can all have 200-horsepower single-cylinder motorcycles that weigh 200 pounds. There are two reasons this isn't possible. The first is that fuel begins to detonate on its own when it’s under lots of compression. (This is actually how a diesel operates; those engines don’t even use spark plugs. A diesel with a compression ratio of 20:1 is not uncommon at all.) This can be staved off a bit with higher-octane fuel and different combustion chamber design, but there is still a practical limit. (It’s also why many new bikes require premium gasoline.) Variable timing on modern motorcycles permits bikes to run on lower-octane fuel, but there’s no free lunch — you won’t be making the best power possible on lower-grade fuel. (It’s important to remember that high-octane fuel is of no benefit if your engine isn’t detonating. Pouring 108 octane into a stock Honda Rebel won’t make it go one lick faster than plain ol’ regular 87.) You don’t want to have to run cans of off-road race fuel for 10 bucks a gallon if you have a hi-po bike, though, so that’s a big part of why compression ratios aren’t sky high. If you’re like 99 percent of people on a motorcycle, you’re usually not competing and have to fill up at a fuel dispenser.

The other reason compression ratios have a practical limit is because metal can only take so much stress. Sure, head design and metallurgy can (and do!) improve, which is part of why higher compression ratios are par for the course at this juncture, but there’s only so much hammering a piston top, ring land, or connecting rod can withstand — and with increased compression comes increased heat, as well. High compression ratios on overhead valve engines usually have valves and pistons getting very close to one another, so the chances of interference-based destruction go up. That leads to a need for more precise valve timing control, which has come about in recent years, in turn leading to higher CRs (and higher motorcycle prices!)

This is sort of a beginning guide to compression ratio; there’s all sorts of nuances we didn’t cover. However, you now know the basics, so this is one more number in a spec sheet that should help you understand a motorcycle's powerplant a little bit better.