To be perfectly honest, I’m sick of this Yamaha DT-1.

Don’t get me wrong. I love the model and certainly have tremendous respect and affection for this particular bike, given that it hauled me 600 miles across Wyoming, but we need some time apart.

That’s because this motorcycle has soaked up a lot of hours and imparted a ton of stress on three separate occasions now, including the initial overhaul before we left for Wyoming, the week I spent riding it across the Cowboy State, and the time we invested in fully rebuilding the bike for "The Shop Manual" video below.

Open up that can of worms

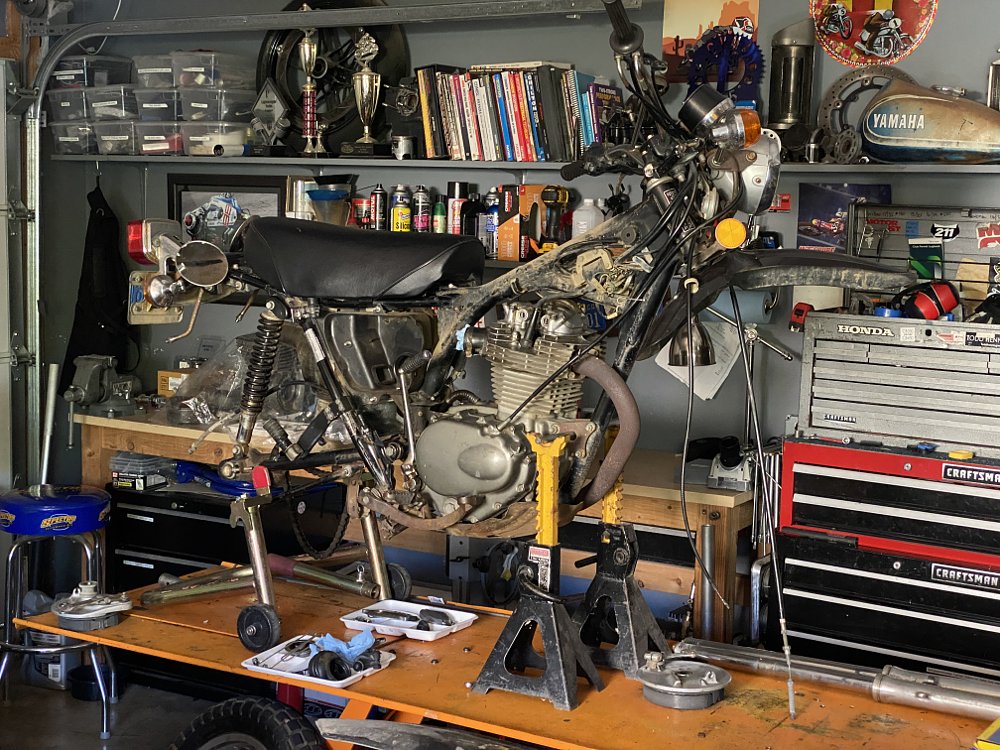

When you’re in the market for a 50-year-old dual-sport and you don’t want or can’t afford a factory-correct restoration, you'd better be prepared for a basket case. Sure enough, our $1,600 Facebook Marketplace buy was all that and then some.

The tires weren’t dry rotted and the tank wasn’t rusty inside, but other than that our ‘69 DT was hammered. While the 1975 Honda CT90 we rode to the top of Alaska only needed a tune-up and normal consumable parts replaced, this Yamaha required an overhaul to even be rideable.

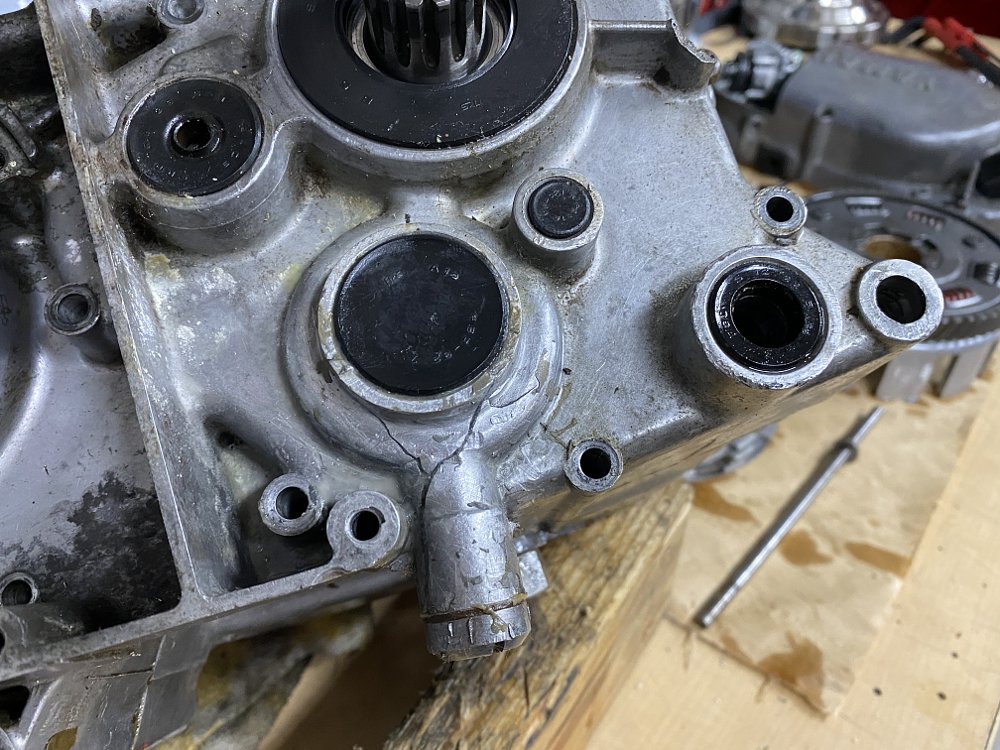

The oil leak I assumed was a bad output-shaft seal turned out to be a cracked case, and a top-end inspection revealed a sand-blasted bore and ring end gaps that I could measure with my thumbnail. Below that, pitted crank bearings. That was on top of dented head bearings, dry wheel bearings, a crumbled air filter, missing 6V battery, leaking fork, seized swingarm bushings, and all the other maladies an old, heavily used, and poorly maintained machine offers. The more I dug into it, the more issues I found, and the two days I’d allotted to fixing it up stretched into more than a week of long days and late nights.

A big part of the delay and a major source of stress was parts availability. Yamaha only made this inaugural model for two years before enacting frequent and major changes, so parts are scarce and compatibility is tricky.

Thankfully, a visit to the once-a-year El Camino Vintage Swap Meet put me in touch with the owner of KDI Reproductions, and I visited his garage several times to scrounge for parts. David donated several junk short blocks that supplied the case half and other pieces needed to triage the DT-1’s bottom end. Unfortunately, he didn’t have a replacement for the bushing that I shattered while disassembling the ultra-rare, steel-lower fork. To fix that, I bought some bearing bronze and got a buddy to turn down replica bushings on his lathe. Another day shot to hell, but at least I got to visit my friend and talented fabricator, Jesse Davis.

Even with all the help, corners had to be cut to get the bike ready in time for the drive to Wyoming. Desperation is an ugly cologne, and I’m not proud of the hasty “solutions” I was forced to come up with, like twisting an exhaust gasket from aluminum foil, making oil-tank bushings from bits of fuel hose, and shortening screen-door springs to hold the header pipe on. And when I discovered that the right side of the axle sat a half inch higher than the left side because the swingarm was bent, all I could do was get the chainline close to straight and hope for the best. Luckily, I have experience riding crooked bikes.

With 24 hours to go until load up, the bike was back together and started easily. After a few heat cycles I took it for a spin around the neighborhood and was dismayed to discover that the transmission wouldn’t shift above second gear, no matter how hard I kicked the lever. An hour later I was fretfully examining the still-warm transmission, referencing the various service bulletins that one source says were rolled out almost monthly during the DT’s early years.

If CTXP’s director Spenser Robert was concerned that I might have put too much of a polish on the DT-1 and ruined any chance for mechanical drama during our road trip, he needn’t have worried. There were still plenty of loose ends when we loaded the bike and started driving east.

DT de destruction

If you watched the CTXP episode or read the article, then you’re aware of about 90 percent of what the DT-1 was put through on its way across Wyoming. It really took a beating.

The edit conveys the bike’s third-gear malady, but only portrays a few of the dozens of times the gear dogs smashed past each other and zinged the revs to the moon. Speaking of revs, we weren’t able to document the tortured death that befell the tachometer and speedometer. On the first day their bushings began to squeal from lack of lubrication and then promptly seized. The tach needle even jumped off its pin and spent 500 miles rattling around behind the glass.

There was also a crash in the snow that didn’t make the cut, after which the DT-1 simply refused to start for the better part of half an hour. That crash also wrenched the throttle assembly and caused the carb to hang up, which made riding the crooked bike in the slippery snow about five times more exciting than I would have preferred (check out the wheel alignment in this riding-away shot). That hanging throttle was also an early clue that all was not well with the throttle cable and its sidekick, the oil-pump cable.

The DT’s initial seizure was also far more distressing than the video’s casual voice-over comment may have made it seem. I recall feeling the engine losing power, followed by that sickening chzwerp of expanded aluminum binding against cast iron. I assumed the trip was over for the DT. Zack and I were well ahead of Spenser and cam-op Andrew at that point, so we danced around the topic, obediently waiting for the camera to roll before discussing the incident and kicking the bike over to see if the piston was truly stuck. Thankfully, it was just a soft seizure, meaning the piston didn’t completely weld itself to the cylinder, but it certainly left plenty of itself in the bore during its trials in Wyoming.

Groundhog day

In a lot of ways, what you’ll see in "The Shop Manual" video is the same work that was done before the trip, just in a calmer and more orderly fashion. There were certainly some fresh procedures, though, and Stephen Gregory’s serene editing belies several hiccups that happened behind the scenes.

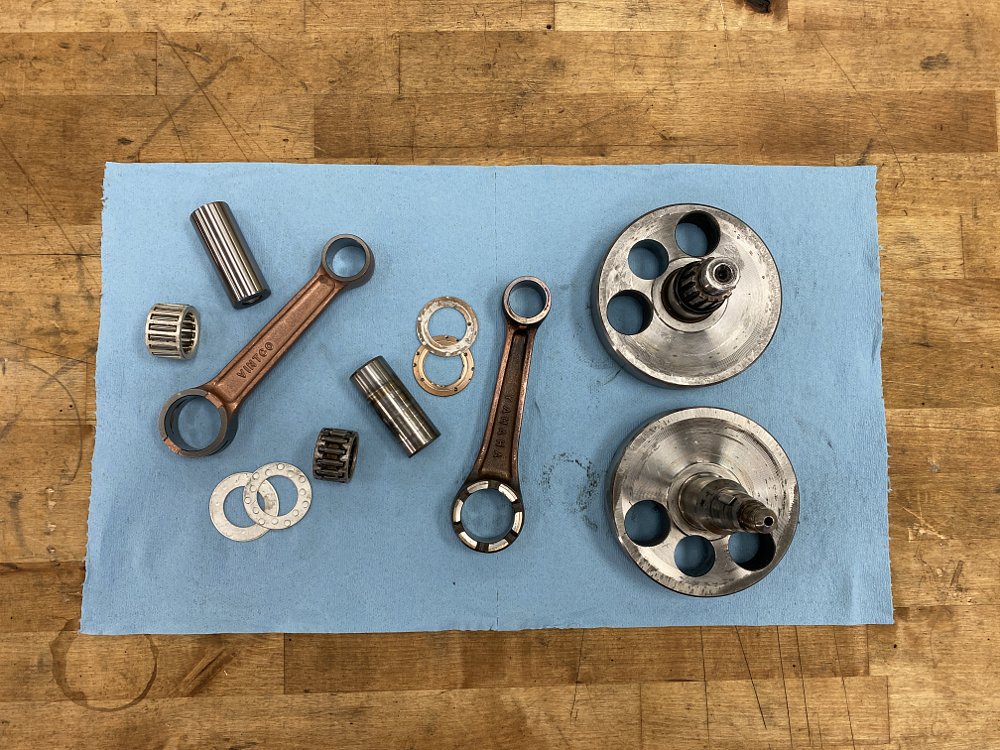

There were snags, like the DT-1 savant who agreed to provide crucial connecting rod/piston/cylinder compatibility info and machining services, then inexplicably ghosted me. That forced a major and last-minute adjustment to the rebuild plan that catalyzed another scramble for hen’s-teeth parts, including a connecting rod. It also moved installing said connecting rod onto my plate, which wasn't something we were prepared for.

Many have asked, so I’ll state it up front: The rebuild took about 40 hours, including filming. Without a camera it could probably be done in half that time. I'll also point out that yes, whacking the crank wheels with a mallet is indeed how you you bring the main journals into concentricity.

We shot the project in two stints, both of which had time restraints due to travel or other projects. The disassembly took place over the course of three days in early December, and we tackled the assembly during five days in early January. The time between was spent hunting for parts and strategizing the story arc of the video, which Spenser and I wanted to feel similar to the CT90 episode, but with its own flavor.

Washing the bike in the back of a truck, tackling the gauge and crankshaft rebuild, working with dry ice to sweat in the bearings, integrating some welding, and modifying the front fender added new visual and aural stimulus to this episode. Meanwhile, we breezed over the things we’d detailed before or didn’t find sonically intriguing, like rebuilding the fork and carburetor, pressing a crease out of the rear rim, and setting the ignition timing.

A big motivation for getting the bike done by a certain date was Zack’s desire to film a Daily Rider episode with it, so that we could create a trilogy of content like we have with the CT90 from Alaska.

The DT was back together in time and the engine runs great (with significantly more compression now that it has properly sealing rings!), but once again there were shifting problems, with no time and zero ambition left to deal with them.

Given how strong the bike runs and how long it’s liable to last after such a thorough overhaul, I’m keen to have it shifting properly. Which means diving into the gearbox. Again. I’ll do it, but not any time soon, because it’s going to be a while before I'm willing to let this bike stress me out for a fourth time.