If you follow the news cycle of the motorcycle industry, there’s a chance that you have gone slightly numb to all of the announcements about new models and new technology. That would be fair. But with all of the features and acronyms that get thrown around every other time a new bike makes a debut, keep in mind that things are changing which we cannot see.

It’s the same story with almost any product we know. A new version of a Honda Civic is new to us because it looks new. The same goes for an iPhone. And sure, the outside shape sometimes matters, but one of the main reasons it’s important to have a new shell or a new look is so that we, the consumers, understand that it’s new. We are given to understand that the functionality of the device or machine has changed because it looks different than the previous model. This is why the word “facelift” is an uncomplimentary term in the motorcycling community, because it suggests the company is trying to trick us. Suzuki’s “new” V-Strom 1050, for example, has the same displacement as the previous V-Strom 1000; what gives? We’ll get to that.

Evolution and resolution

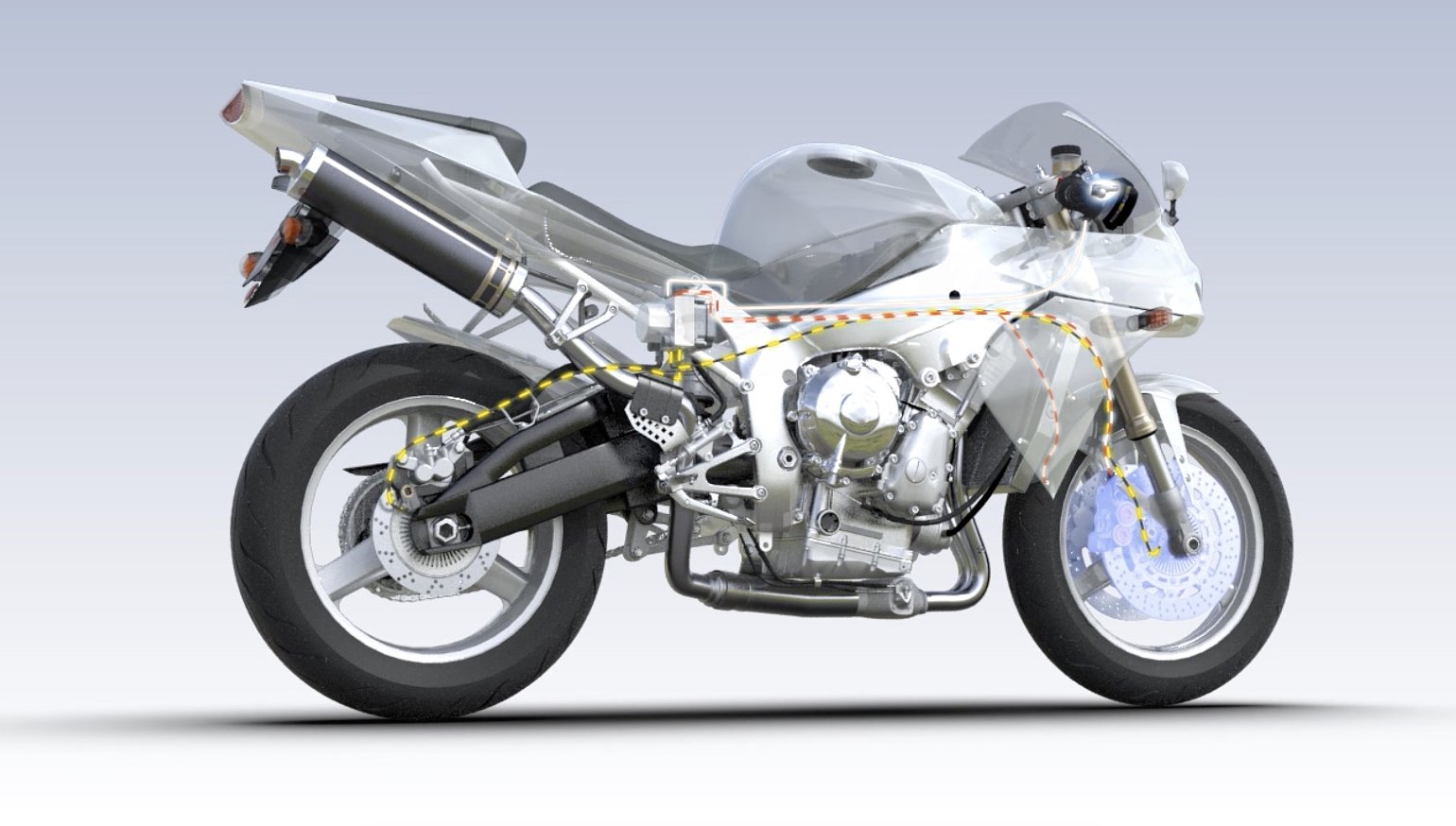

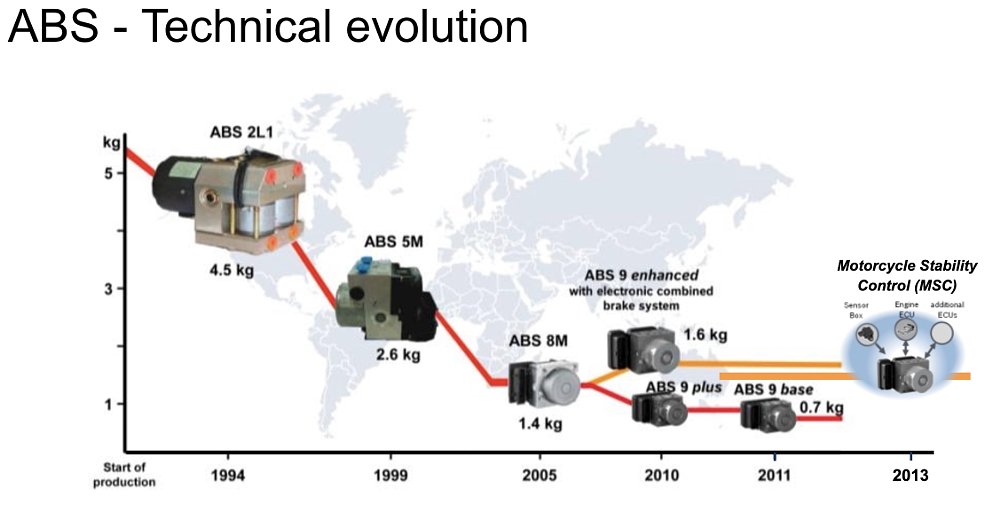

Electronics inside these machines we love evolve just as much, if not more, than the shape of headlights and color schemes, and anti-lock brake systems are probably the best example of why the evolution is important to understand. “Initially we took the ABS technology that was available, based on automotive hardware, back in 1995,” explained Brad Heiler, Global Customer Team Leader at Bosch. “When you look at the hardware point of view, and the evolution of that, the early pieces of hardware weighed four and a half kilograms.” From 10-pound units swiped from the automotive world in the mid-1990s, basic units now weigh a couple of pounds and are about the size of a coffee cup (or smaller). Vinnie Kung, Product Manager at BMW Motorrad USA, went back even further. Rewind 30 years and a BMW K100’s ABS system was a 22-pound chunk of hardware larger than a standard battery.

Fast-forward about 20 years to 2012 and one of my first experiences with anti-lock brakes on a motorcycle, a Honda VFR1200. I powered down a sidestreet leaving the office and as I approached the stop sign I clamped on the front brake to start slowing the 600-plus pounds of motorcycle. I saw the manhole cover in the path of the tires, but didn’t think much of it. As I crossed over the cover the front wheel slipped enough for the ABS to kick in, pulsing the lever and reducing pressure at the pads. Doing its job, in other words. In less than a rotation of the front wheel, the manhole was out from under the tire and traction was restored, but ABS was still engaged. About 10 feet past the manhole the ABS was still not allowing me to add brake pressure.

I started to panic a little. The stop sign was approaching and I had spent what felt like a long time waiting to get control back in my two fingers. After about a half second of pulses (probably around 15 feet at the rate I was traveling) the brake power came back. I stopped in time. The ABS did its job but it was rudimentary enough to give me a little fright, and other motorcyclists might have a similar story about how an ABS system betrayed their trust. Bosch revealed that there is often a great deal of collaboration between a supplier and a company developing a bike, but how each one chooses to tune the systems is different. “Even if the [hardware] features are the same,” explained Heiler, “the character can be tuned to feel different.”

In other words, that experience I had on the VFR1200 might have had something to do with Honda being a relatively conservative company. Remember that 2012 is the same era when the RSV4 superbike used an early generation of Aprilia Performance Ride Control (APRC), which would gently bring back lurid powerslides while carving around a racetrack. It felt hugely sophisticated, because it was. Aprilia was using two ECUs and a fleet of sensors, capable of processing ungodly numbers of data points per second, while Honda’s equivalent CBR1000RR did not have traction control at all. In Karl Dresen’s words, “the spectrum of collaboration can be broad,” meaning companies can simply apply systems to machines without a great deal of refinement, if they choose.

BMW’s Kung pointed out perhaps the most crucial nuance to the massive evolution of electronic rider aids, which is that over the years hardware and software have developed at different rates. Historically, the back and forth of developing systems like this is like trying to make a vehicle go faster around a track. If you add horsepower, soon the chassis and brakes can’t keep up. If all of the focus is put on the chassis, then it handles so well you wish you had more horsepower. The pursuit of perfection creates a vicious cycle, and for a long time — the mid 1990s through the late 2000s — the R&D of ABS was focused on the hardware.

“It was 80/20, mechanical to electronic” said Kung, explaining that as the physical pieces got smaller, “the software development pretty much stayed the same, because we didn’t have all of these other inputs.”

“A great way to look at it is this,” continued Kung, simplifying it even further. “A car, a bike, all of these ABS systems had the exact same wheel sensor for 15 or 20 years — from the 90s to the mid 2000s, maybe even the late 2000s. So, that was the only thing you could base everything off of, and the software could only read that wheel sensor.” The focus was on making the physical pieces smaller, more agile, and able to respond quicker. Eventually, sensors evolved and were applied to other areas of the machine. Suspension stroke, brake pressure, and (with the advent of ride-by-wire throttles) fueling systems were soon all being monitored.

With that, the driving force behind development shifted. “The vast majority of development was on the mechanical side, for probably 15 years,” said Kung. “Nowadays, I think 80 percent of the gains are through software and 20 percent are through hardware.” In other words, monitoring so many different parameters of a motorcycle’s actions has let the fabulously quick data processing of this era to be applied and make an impact. Motorcycles are still behind cars, and probably always will be, but the leaps are still happening even if the concerns over packaging and economics are slightly different.

Karl Dresen, Bosch’s Director of Engineering, breaks the evolution of ABS and modern electronics into three stages. The first was simply stability. “In the beginning,” Dresen said, “we had a technology that would prevent the wheel from locking, slipping, or sliding while braking or accelerating.” Adapting that from cars to motorcycles is something the industry has already accomplished. “Now we’re in the phase of sensing,” Dresen continued. “Ultrasonics, radar, and inertial measurement sensors, which don’t just sense the state of the bike but also the attitude of the chassis and the things around the machine.”

The future? Connectivity, which Dresen says is already being applied. Data flowing between the bike and the cloud, cameras reading road signs, and so on. Dresen imagines a world, “where we can notify the rider of needed maintenance, not based on some rigid schedule but based on actual sensors in the engine and in the brake unit. Being able to determine road conditions based on weather data, specific road information, or another vehicle at a distance coming toward an intersection.”

To some riders, that will be a scary thought, as my colleague Mark Gardiner reported a couple of years ago. Then again, some people will have been (or still are) skeptical of an ABS’s ability to help rather than hinder, and we have very much arrived in that era. The technology exists, it’s a matter of if and how manufacturers apply it to their machines. As always, you the consumer should feel compelled, maybe even obligated, to hold your favorite publications or websites (*cough* Common Tread) accountable for telling you which systems are good and which ones aren’t. Sometimes these evolutions even happen without a press release.

Progress in perspective

If you offered, 30 years ago, to take a family photo with your telephone, someone would probably ask if you were concussed. That same offer 15 years ago would get some skeptical looks. Today, it’s as obvious as anything that you would use your phone to take a picture. Point being, if you bailed into a rain-soaked curve 30 years ago and grabbed a handful of front brake, well, that would be a good way to end up with an actual concussion. Now, a new motorcycle has a decent chance of understanding your speed, lean angle, and the maximum allowable amount of brake pressure for the situation.

At this point it’s only fair that I circle back to that V-Strom 1050 I poked fun at earlier. The engine has been revised with new cams and pistons, so it makes a little more power. But anyone who has ridden a V-Strom 1000 will tell you that the engine didn’t need anything; it’s a great mill either way. The point is, having the same engine displacement doesn’t tell the whole story — it has loads of new technology that set it apart from the previous model. It has cornering ABS, as well as a new ECU and various ride modes, plus the addition of cruise control. Real advancements, in safety and comfort. Worthy of changing the name so that we will recognize it as new, in my opinion. And yes, it got a facelift.

The critical context to understand is that all of this evolution is relatively recent. It was only in 2009 that Bosch developed a physical ABS unit specifically for a motorcycle, not one that was hijacked from the automotive world. And it was 2013 when Bosch first applied an IMU to a motorcycle — that was the company’s fifth generation IMU (dating back to 1998), and in 2020 it is using the seventh generation. Things are moving quickly in this world, and we as motorcyclists owe it to ourselves to cast a critical eye to what is changing and how.