How is motorcycle gear designed? And who gets to create the next helmets, apparel, and hard parts to hit the market?

Meet Roger Sgarbossa, Comoto’s Vice President of Branded Products, and Ed Wildman, Exclusive Brands Product Manager. They manage a sprawling portfolio of motorcycle gear, and their passion for riding reaches every corner of their domain.

When RevZilla and Cycle Gear joined forces under parent company Comoto, Roger and Ed were tasked with a key assignment: reimagining exclusive brand lines like BILT, Sedici, and Street & Steel. The new REAX brand also needed a guiding hand as it developed an identity of its own.

The rebuilding and rebranding would be a mountain of work, but Roger and Ed were ready for the challenge. Roger brings plenty of design experience from the action sports industry, not to mention a leading role in launching the Roland Sands Design brand under the MAG Group. Ed has an industrial design background, and he previously served as RevZilla’s foremost gear expert for all product reviews. Both are accomplished riders with garages full of motorcycles. There are plenty of roles within the motorcycle industry that do not require riding experience, but when it comes to moto gear design, Roger and Ed both believe riding is a non-negotiable.

How is motorcycle gear designed?

Roger says it takes about 18 months for a product to go from concept to in stock on the shelf, or a few months longer for helmets. Every product they work on is designed from the ground up. With anywhere from 60 to more than 100 products in development at a time, Roger and Ed keep busy year-round as they create, test, and refine tomorrow’s motorcycle gear.

The process starts with Ed’s product research and merchandising expertise. After the research phase, concept products are penciled in across the different lineups. The concept products are shown to buying groups, who review the details, approve the most promising options, and ultimately establish the quantities they’ll need for the next riding season. (Motorcycle gear is typically released in two seasons: spring/summer and fall/winter.) This leads to design briefs, after which concepting turns to prototyping and testing. Then, there’s another review to make sure everything’s on target before production begins.

“There’s no reason why any product we introduce shouldn’t be successful,” Roger says. Industry experience and customer feedback provide helpful direction when creating the next season’s gear.

“Now that we have these brands, we can make them the way we want them to be,” he explains. “We want great gear that doesn’t break the bank, and keeps people riding... We’re filling gaps in the gear world with unapologetic product. You shouldn’t have to justify riding with anything we create.” Of course, Ed and Roger spend plenty of time trying different gear out on their personal rides.

Less is more

Before the overhaul, Roger and Ed agreed that the brands had way too many products overlapping each other. Streamlining the lineups became top priority before adding new options.

“The first thing we did was take the line plans for all the brands, and lay them out,” Ed explains. “What jumped out at us was, in a single product segment, they had 13 leather vests and seven leather chaps across three different brands… Why? Why would that one micro segment need this many options, with three different brands to carry them? So we focused on what was working, and what wasn’t, and built the brands’ identities from there.”

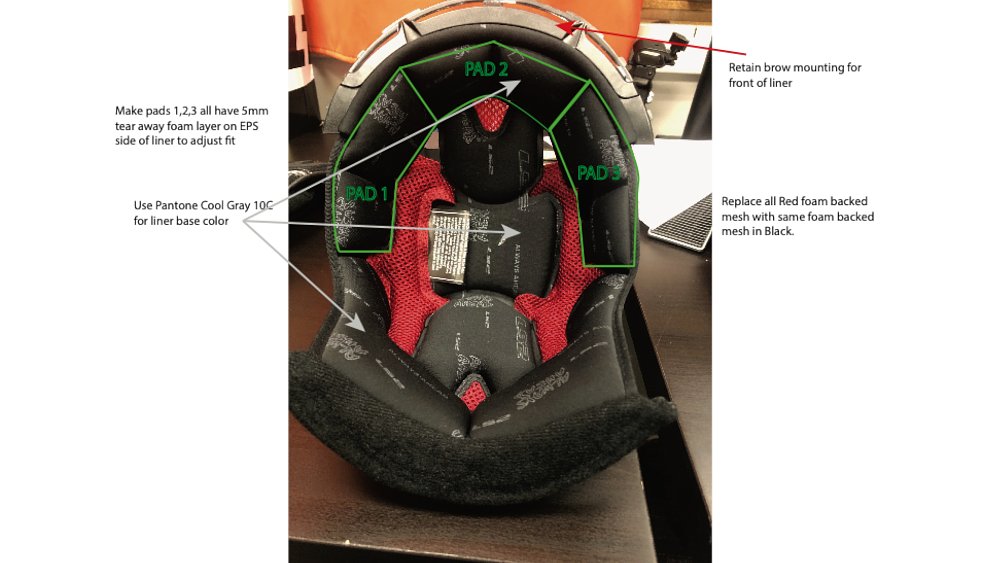

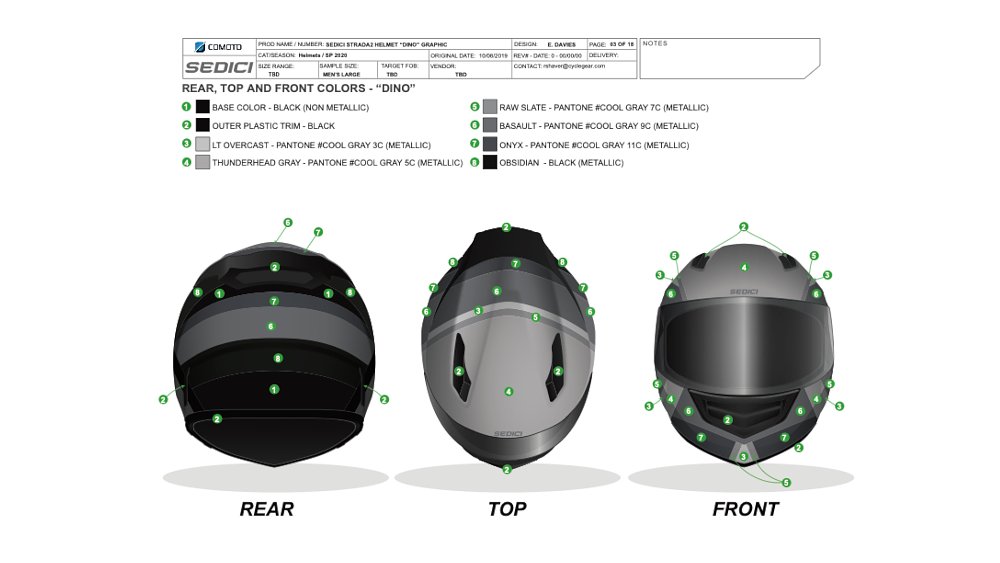

Ed and Roger point to some recent pieces as highlights of their recent redesigns: the Sedici Corsa/Chicane race suits, the Sedici Garda ADV line, the BILT Lux dirt gear, and the Axial base layers. Their Sedici Strada II helmet, another recent design, has already become Comoto's best selling helmet. Roger estimates they’re about two-thirds of the way through updating all their product lines. The work is far from over.

It’s all in the details

Roger and Ed say it’s the little details that separate good from great in this industry, and most of the time, those details don’t add very much to the price. The hard part is taking the time to communicate those specs to the factories up front. Ed says that once the gear is available for sale, first impressions are easy: The customer likes the gear, or they don’t. It is during the discovery phase, the first few months of ownership, that these details earn their keep. An example? Jacket pockets that zip down to close, instead of up, for easier access while on the bike. “Every time I see [our flipped zippers] in comments, it's one of the biggest compliments,” says Ed.

Other examples include color-coded thermal liner snaps, collar snaps to prevent flapping, waterproof phone pockets, hidden reflective accents, and zipper pulls big enough to work with a gloved hand.

“Any one of them by themselves doesn’t mean much in the moment, but hopefully, when you're riding or you're using it, it's that ‘aha!’ moment or that discovery moment when you know you made the right choice,” says Ed. “It takes some extra work, that’s all. Just because you're building a budget-oriented waterproof jacket, for example, doesn't mean it has to be a non-breathable sweatbag. We can add features at price points where you wouldn’t normally see them if we focus on getting it right.”

Finding the customer

The new REAX brand served as a helpful test bed for some of their new ideas because it didn’t have any of the history or preconceptions that existing lines did. After launching REAX (Ed called it “a step up… a tidy brand and one of those quiet success stories”), they relied on market research to develop identities for other lines. BILT riders logged the most miles, so it’s no surprise that they valued durability and essential protection. Sedici customers were upmarket and aspirational, often riding sport or ADV bikes, and they wanted a more premium product. The Street & Steel crowd wanted cruiser/custom gear that could pass for street clothes while off the bike. Regardless of brand, Roger and Ed are careful to design for protection and features first, and price second.

“Sure, we could try to make the cheapest gear on the market to win on price,” Roger says. “But we never will. That’s a race to the bottom. Yes, we have an idea of price point for each product we design, but the gear has to work first and foremost.”

“If we if we can't make [gear] work the way we want, then we're not going to do it,” adds Ed. “Cutting corners just leads you down a very downward spiral, which is only going to hurt in the end, you know, and bad animosity with riders. We've been fighting some stigma over the last few years of improving these brands. It takes time for people to see the changes taking place... A big, big win for us was the new line of Sedici helmets, all new. That was a financial risk, but it's gone on to prove that we can tackle these projects and deliver on them. I’m glad that leadership is open to this. Yes, people people want good value, but they want good product first. Features mean more than a logo to a lot of customers.”

Looking ahead

Although Roger and Ed can’t divulge too much about all the upcoming products they’ve cooked up, they agreed to a few teasers. “By the spring of 2022, we'll have pretty much turned over every product in the soft goods lineups,” Ed says. “It's been a big lift. Now, we can really start going in for some bigger changes. We’re working on a new armor line, all CE-certified. We want to be a leader in protecting more motorcyclists.”

“I started riding in the in the early '90s, and there was a massive chasm between good gear and junk,” Ed remembers. "If you didn't have money, you either didn't buy gear, or you had terrible stuff. It cost a fortune to get anything that had real protective value to it. What makes me happy is that we can offer a good range of gear that does what it's meant to do. Even our entry-level gear is miles ahead of what used to be available.”

How is better motorcycle gear designed? With your help

Roger and Ed take feedback seriously, and they agree that that leaving a review or YouTube comment is the best way to communicate ideas back to the designers. “You just need to tell us,” Ed says. “We're listening, we're looking at reviews, and we’re always looking to improve. Feedback helps us make things better for the next rider…” One example was a model of men’s riding jeans with too low of a rise for some riders. Sitting on a motorcycle could show too much moon, and an updated version with more coverage was quickly rolled out after reviews brought the issue to the team’s attention.

“In a way, a four-star review is more helpful to us than a five-star review,” Ed says. “It’s nice to know that we didn’t miss the mark. Four-star reviews tend to come from riders who are thinking critically about gear. We are always looking for ways to improve."