This winter, I called up a friend and we were catching up some, and he asked me if I wanted to come over and have a few bottles of suds in his garage. Being the avid alcohol enthusiast I am, I agreed, and then he asked if I wanted to help him tune a motorcycle while I was there.

Sure. Why not? I'll admit to being slightly puzzled, as Chris, the friend in question, is pretty mechanically savvy. The specimen requiring our attention was a 1957 Harley-Davidson XLA (Ironhead) upon which he races flat track. He has a Super E carburetor fitted to it. A Super E, for those of you who haven’t ever fiddled with one, is a Stone Age device, very simple. A chimpanzee could tune one of these. And that little dichotomy is the beginning of my day which culminated in the successful installation of coolant into motorcycle that has no place in which to pour it.

To bring us to that point, I'll walk you through some of the basic engine performance diagnostics that helped us ferret out this bike's malady. Deducing what’s wrong with a motorcycle usually involves some testing and some thinking, and most mechanics who are good at it can talk you through the process and their rationale, rather than simply unbolting and inspecting items willy-nilly.

I headed over to Chris’ shop, which was (mercifully) heated, and he’d already thought to warm the bike up for me. I was pleased; it would save us time, and you don’t want to tune a cold bike. I asked him to make a few test rips on it, and it sounded a little ugh, for lack of a better term. His main complaint was that the bike didn’t want to have the throttle “snapped.” You kind of had to roll into it before the engine would wake up.

Funny, because that’s exactly the problem the Super E was designed to cure. It’s a descendant of the Super B, which was a similar carb, but the E was granted an accelerator pump, specifically to allow a rider to crack into the throttle with aplomb. I checked to make sure the accel pump was squirting a nice strong stream, thinking perhaps the diaphragm had a leak, which would lead to the exact symptoms he was having. Alas, the nozzle was pouring fuel into the carb’s mouth in strong, steady jets. Scratch that idea.

I turned the accelerator pump off totally, thinking we could ascertain what jets were in the carb. Chris didn’t know what was in there, and I had shown up with a Ziploc baggie full of jets. Pulling the bowl to check wasn’t hard, per se, but he told me this bike had previously run great with the jets in it, so I was loathe to check them. Turning off the accelerator pump is sort of the first step when tuning these carbs so you can home in on the correct jets. The accel pump can sort of mask incorrect jetting choices, so removing it from the equation simplified tuning.

No matter how I leaned or fattened the idle circuit, the bike didn’t seem to respond. His particular Super E was made prior to 2004. That’s important because Super Es made after that date have an adjustable air bleed to ease the transition from the intermediate jet to the main jet. However, that didn’t seem to be the problem here. After a few frustrating test runs with seemingly little change, I mentioned to Chris that his front pipe seemed to be throwing a lot of smoke on decel. After a few more runs with us fiddling with settings, my mind sort of settled on that smoke. It was like a popcorn hull stuck in my teeth; I couldn't let it go. I began thinking there was a mechanical problem, and I think Chris agreed, which explained why he wanted another brain to put his head against. (Joke's on him, he got the short end of that bargain.)

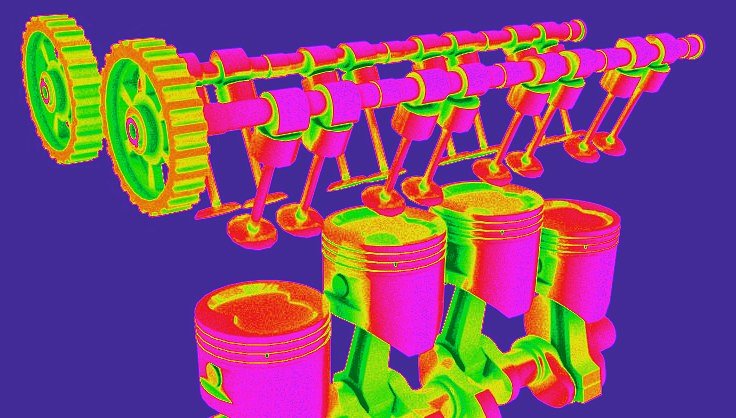

I asked Chris to pull his spark plugs, and they looked a bit oil-fouled. Not crazy, but there was definitely noticeable oil deposits accumulating on the plugs. When he told me there were only about a hundred miles on the plugs, I had a pretty good idea forming in my noggin of what was happening, but testing needed to continue. My suspicion was that the valve guides had begun to wear into an hourglass shape, and were letting excess oil from the head stack up against the valve, releasing the oil into the combustion chamber along with the air and fuel that had stacked up behind it. (Valve guides normally begin wearing in that shape because as the valve tips off-axis, the ends of the guide receive most of the wear. Once the process starts, it gets bad in a hurry.)

At this point, I asked him if he had a compression tester and a manual stating what the specs were. He went digging for a manual, and while he did, I was doing a bit of mental math trying to figure out what the numbers might be if the manual was not forthcoming. (If you’re fuzzy on testing compression, this is how it’s done. I talk a bit about the math I was working out trying to best-guess a spec to shoot for.) My math yielded 129 pounds. Chris found his manual, and the manual called for 120 pounds, with no more than 10 percent variance between cylinders. (Not too shabby for an estimate, eh?) We began the test, and the rear jug blew 125 pounds. The front, however, topped out right at 100. Buh-oh.

Now, this would have been the time when a good diag tech would perform a wet compression test, but I skipped that, being fairly confident in my diagnosis. (I also should probably renounce any claim to being a good diag tech at this time, too, I suppose.) Sadly, we didn’t have a leakdown test rig, either, which meant that we had to rely on my supreme (over)confidence. Instead, I suggested that we needed to start disassembling a few things.

This may sound severely premature to some of you, but remember, this is a race bike, with no overhead cams. They come apart very quickly, at the cost of a few dollars’ worth of gaskets to put it all back together. Off came the carb and intake, pipes, engine mount, and front pushrods. Hell, we didn’t even have to take off the tank. The longest part of the job was getting the rusty pipe and hardware to give up its hold on the exhaust spigot! Thirty minutes later, we popped off the complete head and stared into the jug.

There was more oil in there than I thought appropriate, boosting my confidence. Now, remember how we didn’t have a leakdown tester? Well, there’s a way around that, and that’s where the antifreeze comes in. This is more of a go/no-go test, but it is still a good one. If the combustion chamber cannot seal, compression numbers will be poor. Now, the valves need to seal up against their seats a pressurized, mostly gaseous mixture of air and fuel. However, if they cannot contain a liquid at atmospheric pressure, they’ll never seal pressurized gas. So we upended the head, filled the combustion chamber, and waited.

Why antifreeze? Glad you asked. Unlike something more viscous, like oil, it finds leaks fairly easily. Unlike a flammable solvent, it doesn’t evaporate very fast and sitting out uncovered isn’t dangerous or flammable in a confined space. (But keep your shop cat at bay if you’re doing this.) Can you use water? Yep. But if you don’t want to worry about rust (It’s an Ironhead, remember?) antifreeze should be about perfect because it has rust inhibitors in it. It also has one other nice little feature that’s not insignificant: It’s green! It usually shows up well in a carboned-up port.

So we sat back and shot the breeze for a little while, and in about seven minutes, it looked like the level in the combustion chamber was dropping. We poked a flashlight into the ports and found coolant. So Chris is in for a head rebuild now. Is the intake guide worn, too, and allowing oil past? I’m betting on it. But it was getting dark, and Mrs. Lem had made a lovely dinner of salmon and spinach poached in coconut milk, and there was no way that Ironhead was going back together that evening, so I bid Chris adieu.

The valves will come out for inspection, of course. And at that point, the wear in the guides and the seats will be inspected, along with a few other items. While these can be serviced, cut, ground, and lapped in by a skilled home mechanic, most folks will likely elect to turn the head over to a machine shop, still assembled.

If you’ve got a valve spring compressor, removing the valve springs, keepers, and collars would be the next step — but not everyone has the tooling or know-how to continue on from this point.

Happily, though, without major surgery you might now have an affordable test you can use for diagnostic purposes utilizing a common item you probably have in the garage.

Happy wrenching!