Testing the stator and regulator rectifier is straightforward, and you don’t even have to remove the components from the bike. You just need access to the stator wires, the specs for your bike’s stator (check your shop manual), and a decent multimeter.

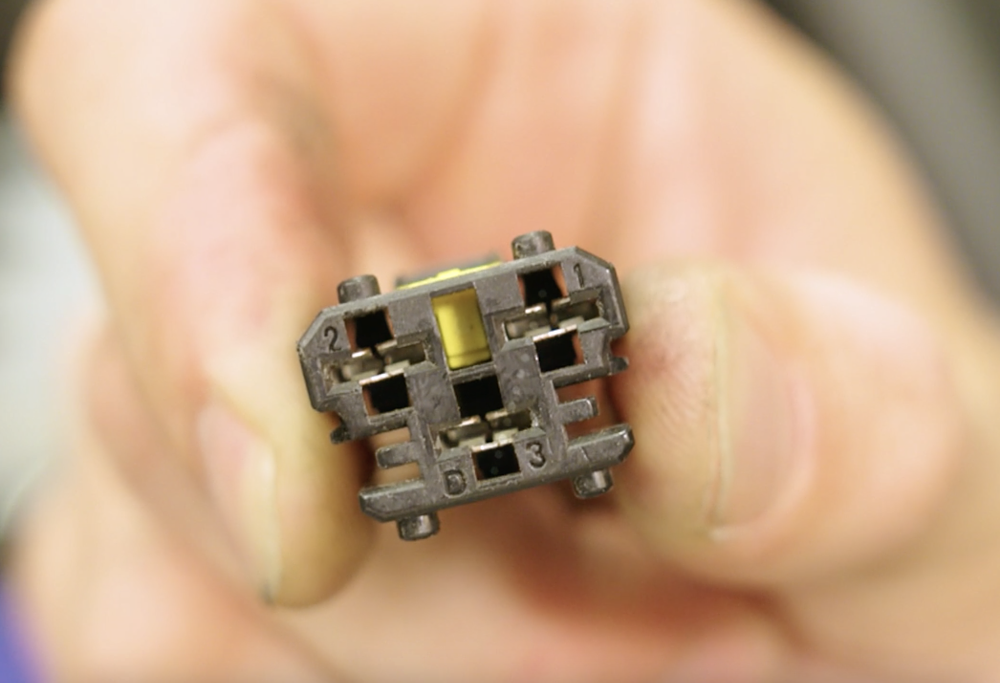

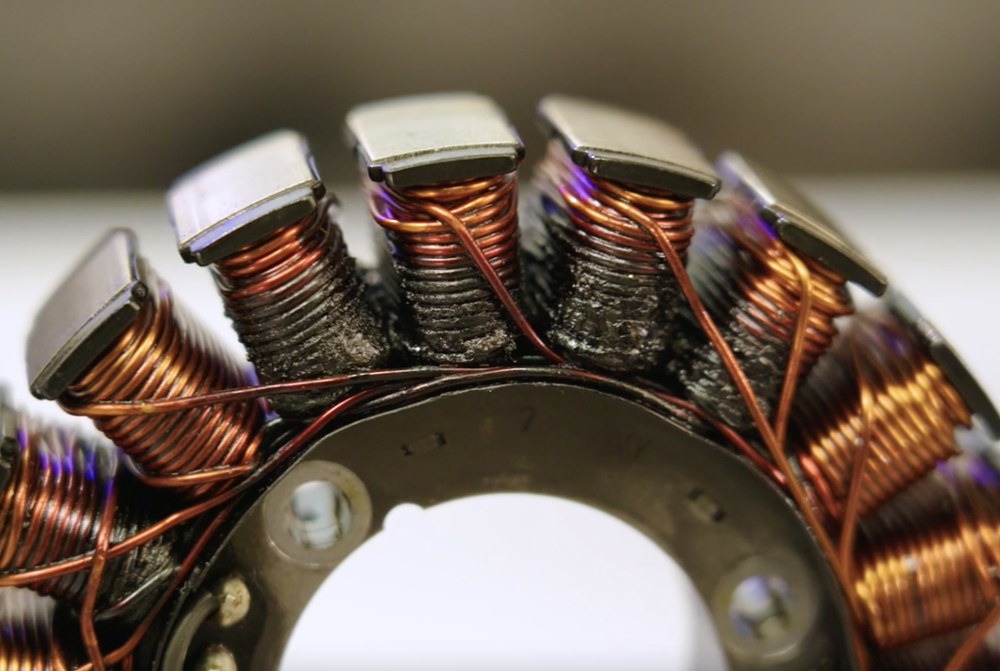

The stator is the source of your bike’s electrical power, so it’s best to start your analysis there. To test the stator we need to expose the wires that come off it, so look for the harness exiting the top of your engine’s ignition cover. Most modern stators contain three windings, so there should be three wires of the same color. They’re often yellow, but white or black wires aren't uncommon, and they might be in a connector with other wires or isolated in their own plug.

Follow the wires to their connector and unplug it so you have access to the terminals, then set your multimeter to Ohms so we can check resistance. The objective is to check the resistance between each of the stator’s three windings, so you’ll be using the probes of your multimeter to connect wire 1 to wire 2, wire 1 to wire 3, and finally wire 2 to wire 3.

Carefully insert your probe into the connector to test the different stator legs, and take note of the resistance. If the reading is outside of your bike’s specs, or if the meter reads OL, meaning Open Line, then there’s a break in the winding and the stator will need to be replaced.

Another reason your stator might be bad is if the insulation around the winding has broken down, usually due to overheating, and is allowing a short to ground. To test for that, place one probe on the battery’s negative terminal or any unpainted part on the chassis so it’s grounded, and then put the other probe against each of the three stator wires. There shouldn’t be any continuity, and if there is it likely means there’s a breach in the insulation and you’re in the market for a new stator.

Different makes and models have different resistance ratings for the stator windings, and if your bike’s resistance range is small and specific, say 0.22-0.32 Ohms like on some Yamahas, know that unless you’ve spent $400 on professional equipment, your multimeter probably won’t be sensitive enough to yield accurate results.

In that case, you could do what’s called a dynamic stator test. In a dynamic test, you connect your probes to the stator plug just like we did for the resistance test, but this time the bike is running and you have your meter set to AC. You should see about 20 volts on each leg at idle and it will rise to 50 to 60 volts by 4,000 or 5,000 rpm. Keep in mind that during a dynamic test the stator isn’t supplying any electricity to the motorcycle, so make sure your battery is fully charged so the bike runs properly.

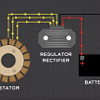

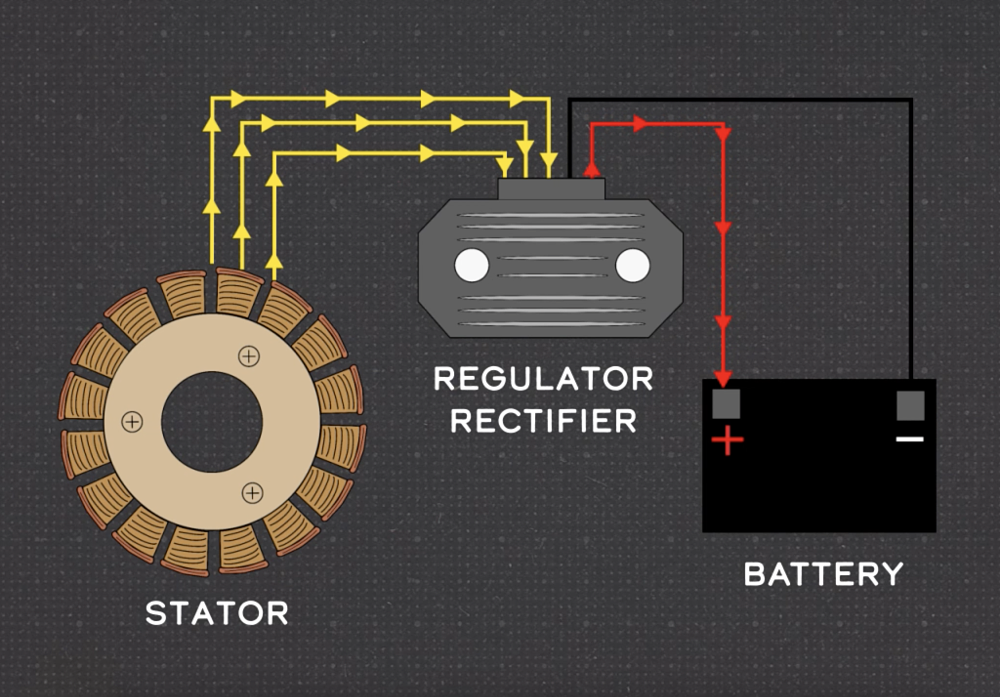

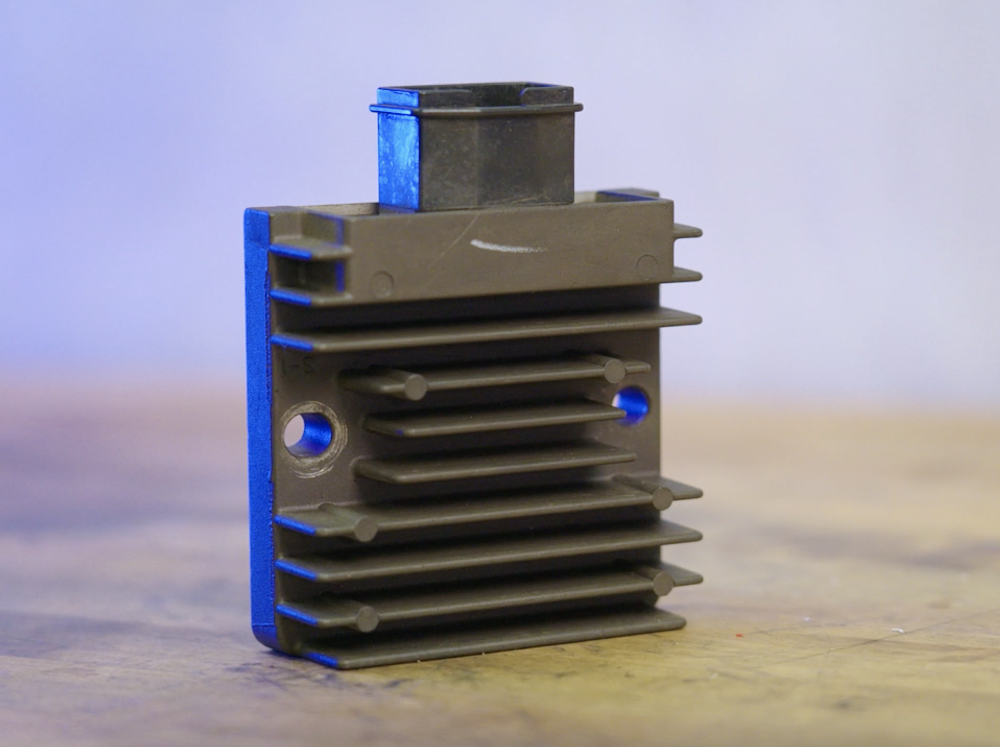

If the stator checks out but you’re still having trouble with the battery under or overcharging, then the regulator rectifier may be the problem. The reg/rec serves two purposes, as the name suggests. It’s got diodes that only allow current to flow in one direction, converting the stator’s AC voltage to DC, and there’s regulator circuitry that acts as a throttle to keep excess voltage from cooking your battery and burning out your lights.

Testing the regulator rectifier with a multimeter is tedious, and you can only evaluate the diodes responsible for rectifying. So if you’ve already tested the stator and it’s all good, then the best way to determine if the regulator/rectifier is functioning properly is to check the voltage at the battery while the bike is running. That reading will let us know if the current coming from the stator is being rectified, and regulated.

Switch your meter to DC, and we’ll put it in the 20V range, connect the probes to the battery, start the bike, and bring the revs up to 4,000 to 5,000 rpm. You should see between 14 and 15V. If you do, then it’s safe to assume the reg rec is doing its thing. If you see a number that’s lower than 14 or higher than 15, check the wiring connecting all these components to make sure it’s intact, inspect the connectors to ensure they’re not loose, corroded, dirty, or damaged, and of course check the fuses. As always, check the simple stuff first, but if everything looks okay, then you’ve effectively narrowed the culprit down to this guy.

Why do these components fail in the first place? Most of the time, it’s due to overloading. The stator is matched to the bike’s electrical requirements, so if you add a bunch of electrical accessories or keep nursing a dying battery, that puts more stress on the stator. Same goes for the regulator rectifier, but a loose or corroded ground can also kill a reg/rec since shunting to ground is how the regulator does its job.

So keep your battery fresh, resist the urge to add a bunch of heated gear and fog lights, and your charging system should keep working for a long time. And if it starts acting up, now you know how to pinpoint the problem.