Would you believe that a top-of-the-line Ӧhlins shock is only slightly more complicated than a run-of-the-mill carburetor?

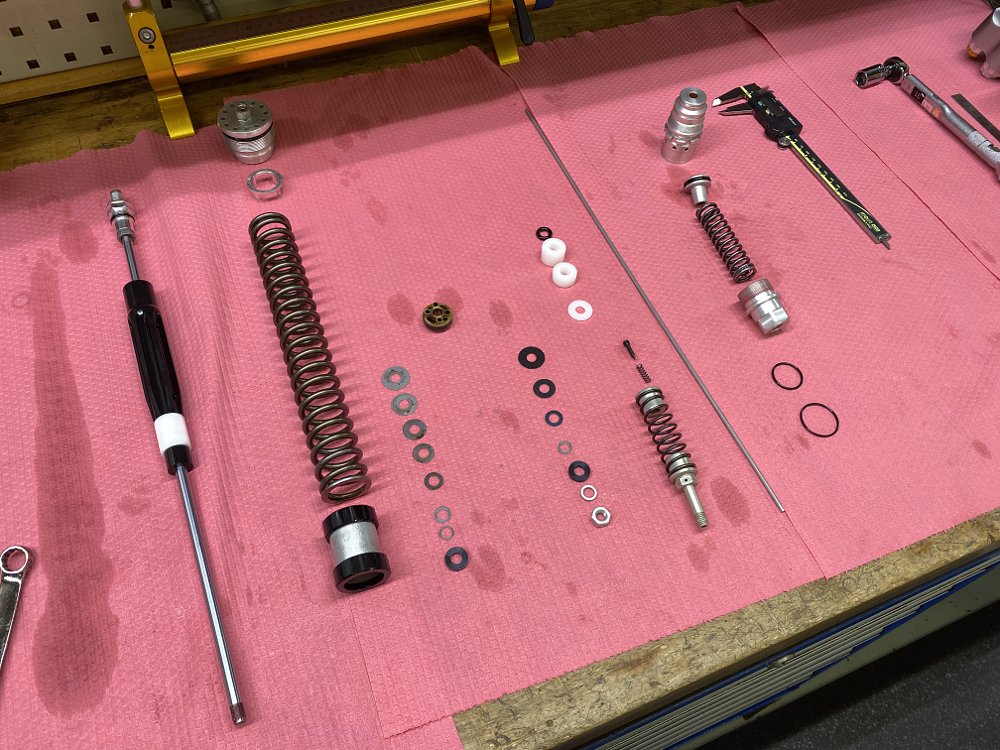

I wouldn’t have accepted that before getting some hands-on training with Ӧhlins, but after tearing down various Swedish suspension components, it rings true. Sure, you need lots of special tools to disassemble a shock or fork, but the work is similar to rebuilding a carburetor, and you end up with approximately the same number of peculiar little pieces.

That’s just one of several unexpected things I learned (as opposed to the anticipated stuff about springs, shim stacks, and the like) while taking a condensed version of Ӧhlins’s Servicing Dealer Training at the company’s U.S. headquarters in Hendersonville, North Carolina. Here’s what else I was surprised to glean.

NASCAR and nature

Ӧhlins has branches in Sweden, Germany, Thailand, and the United States. Its American office is in a quaint mountain town on the slopes of the southern Appalachians, and my first question when arriving was, “Why here?” The answer is twofold: NASCAR and nature.

Ӧhlins expanded into the United States in 1996 to be part of the thriving NASCAR race scene (Ӧhlins is still involved in NASCAR as the exclusive suspension supplier), and Hendersonville is a day’s drive from most of the big races. Plus, the rural, forested region reminded Ӧhlins founder Kenth Ӧhlins of his hometown north of Stockholm.

More weird vocabulary

Suspension has its own lingo that we’ve surveyed before, and now I have two more flashcards to add to the deck.

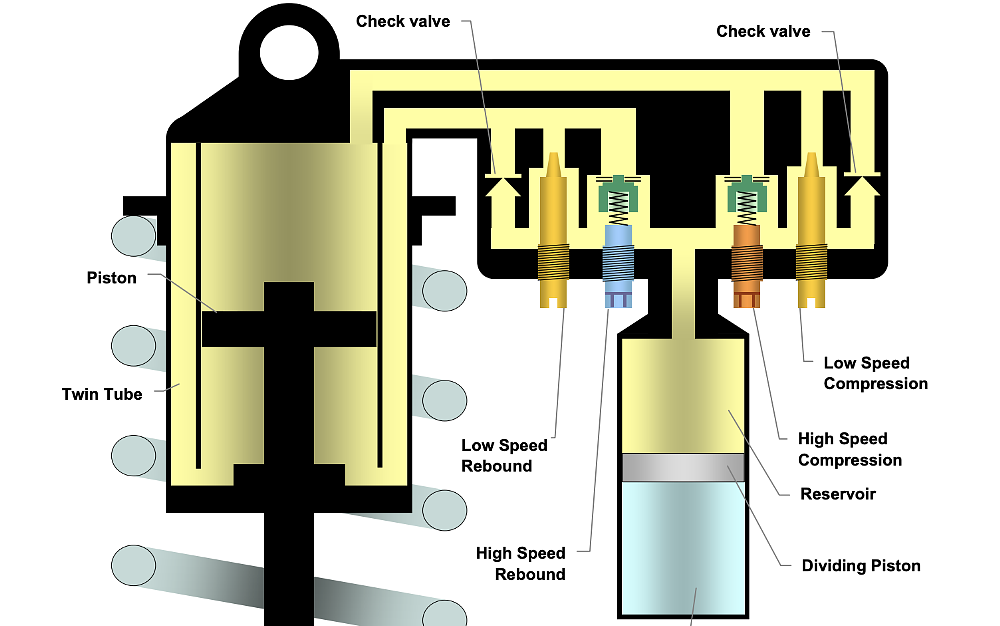

Crosstalk is a phrase culled from the world of electronics, and refers to a phenomenon where a signal in one wire creates an undesirable effect in another wire. The same thing can happen in the damping circuits of a suspension component, but it’s due to shared oil passages, not electromagnetism.

Hysteresis was another new-to-me word, and, in simplest terms, it’s when force and movement are out of phase. The concept of hysteresis is applied to everything from magnets to economics, but in the world of suspension it describes damping force lagging behind the suspension stroke that creates it.

Ӧhlins is American-owned. Twice over

You mean, Swedish Gold isn’t Swedish? Nope, at least not according to the legal documents.

Similar to the way Ducati is owned by the Volkswagen Group, which is owned by Audi AG, Ӧhlins is owned by an American company that lives in another American company’s portfolio. More specifically, Ӧhlins was sold to Northville, Michigan-based Tenneco Inc., a long-time partner in the automotive sector, in 2019. And Tenneco Inc. was purchased by New York-based Apollo Global Management, Inc., in 2022.

Architecture is (almost) irrelevant

A part of me always assumed there was a technical reason for different shock configurations, i.e. piggyback versus remote reservoir, but it turns out they’re just different packaging options.

Piggyback shocks are typically model-specific, since the component orientation has to fit the constraints of the bike, while remote-reservoir shocks are more of a universal product, thanks to the fact that the reservoir can be mounted just about anywhere. The only real performance differences are weight (remote reservoir tends to be heavier) and the fact that a remote-reservoir shock may allow you to put some distance between hot exhaust parts and a portion of the damping oil.

Soap grips!

At each of the service stations in the Ӧhlins shop, there’s a bottle of Dawn dish soap. It’s not for keeping the stainless-steel workbenches clean, but for spraying on shaft-holding fixtures before clamping them in a vice. Why? Because it makes the clamp hold the shaft more securely. Seriously.

I asked Professor Jimmy about it during our last trail ride together and it surprised him, too. My theory is that the soap’s low surface tension allows it to fill the microscopic peaks and valleys on the shaft and clamp faces, increasing the surface area and creating a better seal between the two planes.

If you have a better explanation, please, put it in the comments.